| Heatsink Lapping Guide - Page 2 of 2 |

Posted: January 18, 2004

Author: Dud3!

Manufacturer: N/A

Source: N/A

Comment or Question: Post Here

|

|

It gets tricky now, you may have to do this a few times before you get it. You must remove the heatsink from the paper without scuffing the 2000 grit finish, You can try just bringing it to a stop and lifting straight up, or sort of "taking off" like a plane while you're sanding.

Once you get it off the sandpaper scuff-free, you can either stop now and clean it with denatured alcohol before installing, or proceed to the next page to polish it.

Once you get it off the sandpaper scuff-free, you can either stop now and clean it with denatured alcohol before installing, or proceed to the next page to polish it.

Now that all the hard work is done, it's time to polish the rest of the scratches off to maximize the contact patch and make it look great.

I used my 6" orbital buffer for this, but the best thing to use is a rotary buffer. Either one will work fine, so don't worry about buying a rotary if you have an orbital. If you don't have either one, you can get an orbital buffer for $20 or less that will be good enough for polishing the heatsink.

Assuming an orbital buffer, you need one foam bonnet and one terry bonnet (do not use wool or synthetic wooly bonnets!). The actual polish is an aluminum polish such as the Mother's Mag & Aluminum Polish I used.

Start by putting the foam bonnet (yellow one in picture) on the buffer and smearing a good bit of polish around it. Hold the heatsink so the the buffer will be turning along the length of the base (like the sanding) and run it for a few minutes.

I like to move the heatsink from the center to the outside and back while buffing, and end on the outside applying very light pressure. With my buffer, this lets it turn to get a rotary buffer effect besides letting it turn faster.

After you're done with the polish, remove the foam bonnet and put the terry bonnet on. Buff the remaining polish off to a perfect mirror finish.

Now you can clean it with detergent and water to remove polish, metal, and sandpaper remnants from the heatsink. Dry it with a 100% cotton terry towel to avoid scratching the base, then dry the water from between the fins with a hairdryer or just let it sit a day before you install it.

To remove the polish from the base of the heatsink, use a clean terry towel and denatured alchol. Rub the base several times, using a clean part of the towel and more alcohol each time. Don't use rubbing alcohol or nail polish remover because it leaves contaminants behind that hinder heat transfer.

Your heatsink is now ready to install on your processor! Will it make any difference in the temperature? It did with mine, although I can't give an exact figure. Depending on the thermal compound used (I used Shin Etsu X-23), and the method used to apply it, your results will very of course.

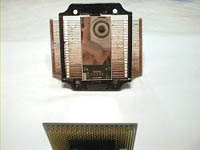

I'll end this guide with a picture of the finished product ready to be installed. At the time I did this, my idle temp after two days with Shin Etsu X-23 was 35C (case temp is ambient, 23C), and full load is 40-41C with a 45CFM 92mm fan. My SLK-900U is installed on a Athlon XP 1700+ Thoroughbred A core (1.47GHz/266MHz FSB) overclocked to 2.0Ghz/400MHz FSB at 1.70v. Not bad at all for 70+ watts of heat and a medium output fan. Now I have an Enermax 92mm fan and I've enabled the NFORCE CPU disconnect feature so my idle and semi-temps are great (a few degrees above ambient, I've had it at 16C) and load temps are about the same.

Special thanks go to Dud3! for sharing this with BigBruin.Com!

Please drop by the BigBruin.Com forum and feel free to discuss this article.

Page 1 | Page 2 | Home | Forum | Review Index

|

|

|

|