In Use (continued):

Water Heater Exhaust Analysis:

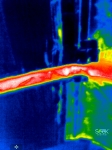

The next scene takes a look at the exhaust of my Propane fired water heater. In my opinion, white PVC isn't the right material for a heated exhaust, but the system has been in place way longer than I have lived there and seems to be in very good shape. What we see in the image below is that cold water is in the exposed pipes on the right, the exhaust gas is sent through the white PVC pipe, hot water is in the insulated vertical pipe towards the left, and Propane is supplied in the black pipe on the left.

The first set of images take a close up look at the blower intake and the very lowest section of the exhaust piping. Since it is black, you know the air coming in is cool - room temperature. But the skin temperature of the exhaust duct is shown as being over 140F - which is the maximum operating temperature of PVC per references I have checked! That bit of piping is going to be getting some extra attention very soon! This image also shows the hot water leaving in an insulated pipe which is barely glowing green, indicating that some heat is getting out, but that overall the insulation is doing its job.

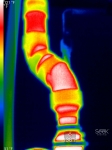

Travelling farther up the exhaust pipe we see that the temperature is high, but below 140F as you get away from the source. Perhaps looking in to replacing the first three feet of this exhaust pipe might be a good idea, and anything beyond that can stay since it is not quite as hot.

HVAC Ducting Analysis:

HVAC Ducting Analysis:

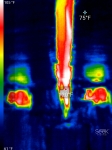

The next set of images will look at some of the ducting from my HVAC system as it leaves the furnace and splits in to the two zones. I had started insulating this area because it would be very warm to the touch when running the heat, and when running the AC it would be very cold and actually get covered in water from condensation. The image below shows everything has been wrapped in silver bubble wrap insulation and all joints have been covered with silver duct tape. I wrapped up that initial area very well, and started to slowly work my way down the duct, and as I went I was only really able to reach the bottom half of each duct - leaving the top half uninsulated. Lets see what that translates to in terms of retaining heat.

The first set of images shows the area just beyond the furnace where the two dampers are located, and where the ducts are fairly close together - meaning I could not get my hands, insulation, or duct tape up in there. Overall, the surfaces are now very well insulated, but you can see a decent heat signature under each damper controller, and up in the crevice where I could not insulate the duct surfaces. It is pretty

cool to me how the silver insulation on the upper portion of duct reflects the heat from below the damper making it look like a second set of warm spots exist...

The next images shows the area where the ducts have an S curve, and is about where I ran out of insulation and ambition for this project. The skin temperature is cooler as you get away from the furnace, but I wouldn't mind having it all wrapped, so that all the heat ends up upstairs where it belongs, and not down in the unfinished basement.

The thermal imager shows it is very warm on the uninsulated sides of the duct as the flow travels from left to right. Then at the S curve, the uninsulated area seen is a greenish color showing that it is warm, but not hot. The heated air is most likely missing this surface, like an eddy in a stream just past a rock.