Testing (continued):

The plan is to test the power supply at a few steps between minimum and maximum power, and record the results. This will be done with the power supply drawing in ambient temperature air (which was approximately 18C), as well as with the heat source being used to maintain an inlet temperature of about 30C (temperature was regulated by varying the proximity to the heat source). The manual details a MTBF of 100,000 hours at a mere 25C, while also listing the maximum ambient operating temperature as 40C. Either temperature seems low for rating a PSU, but if you can expect 100,000 at 25C, what will happen at elevated temperatures that are more likely to be experienced?

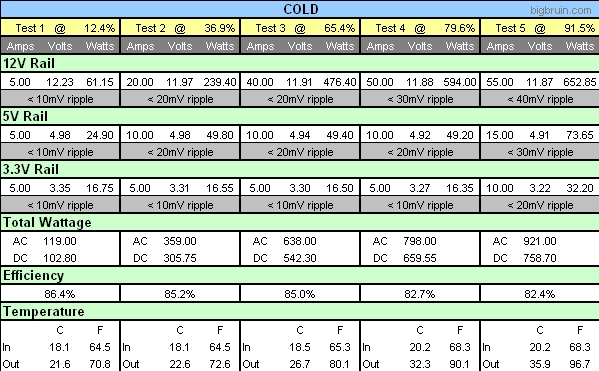

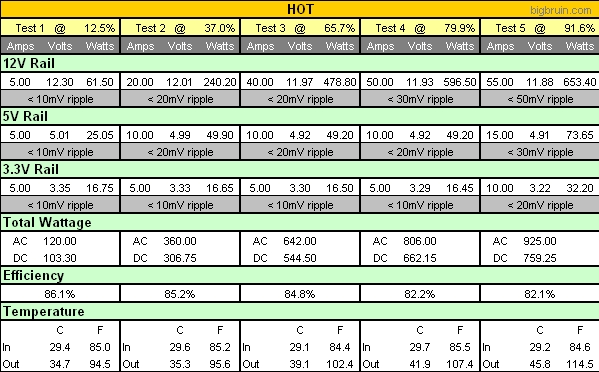

Lets cover what you see in the two charts below. The heading "COLD" in blue and "HOT" in orange indicate whether the test was done at ambient temperature or with the additional heat at the inlet. On the next line we see a yellow background with the test numbers and a percentage in each box. The steps chosen do not correspond to a typical percentage you might test at (ie, 25% or 50%), but were rather chosen to be nice round Amperage values to dial in to the loaders. The percentage value is that of the total load calculated by dividing the total DC Wattage by 829 (the total combined power on the 12V, 5V, and 3.3V rails. The next area on the chart details the electrical data for the three main rails. For example, with test 1, the Amperage on the three rails was set to 5A each, next to that we see the data logger recorded value for each voltage rail, and next to that we see the product of those two values giving us the power. In gray below each entry for Amps, Volts, and Watts we see a ripple value as described previously (and I'll work on getting gear with better resolution some time soon). Below the entries for all three Voltage rails we see a total power field. AC power was read from the AC power monitor, while DC power was calculated by summing the values from the three rails during that test. Dividing this DC power value by the AC power value gives us the efficiency (shown in the next field down), while dividing this DC power value by 829 is where we get the percentage shown at the top of each column. In the final field we see the inlet and outlet temperatures, and since they were logged in Fahrenheit, I converted them all to Celsius for those who appreciate those units of measure.

From the COLD test we see that the unit was tested up to 91.5% of its capacity, and that the electrical performance was respectable across the board. The regulation on all three rails was within specification, with the 12V rail ranging from 12.23 to 11.87V, the 5V rail ranging from 4.98V to 4.91V, and the 3.3V rail ranging from 3.35V to 3.22V. Allowable ripple on the 5V and 3.3V rails is 50mV, while it is 120mV on the 12V rail. While I was not able to get exact values on ripple, what my data shows is that the Ultra Products X4 850W unit does not approach the limits set by the ATX specification. An 80% Bronze certified PSU should have an efficiency of 82% at a 20% and a 100% load, and an efficiency of 85% at a 50% load. While my testing methodology doesn't follow the standard, the results are right there at acceptable levels.

From the HOT test we see the same basic trend echoed from the COLD test. The regulation and ripple are both acceptable, although the range of voltages does increase, as does the ripple at higher loads. Because of this the efficiency drops slightly, but 80 Plus Bronze is still in sight.

I initially intended for the extent of testing to be what was detailed above, but wondered if I could get closer to 100% of the full load and went back the next day for more. Big mistake on many levels. I decided to keep the 12V rail and 3.3V rails where they were for the 91.5% test (55A and 10A, respectively) and to raise the 5V rail to 20A and then 25A. All looked good at 20A, but as I inched towards 25A the gauges started bouncing all over the place and before I could react, thick gray smoke was billowing out of the power supply. I quickly unplugged everything, but the damage was already done! The guys at jonnyguru.com call it the magic smoke, but there was nothing magical about it. It stunk, it was stifling, and somehow my wife smelled it two floors up within seconds. Days later the house still stinks, I am still getting questioned about carcinogens in the air, and my testing lab has been officially banished to the garage (probably should have started there anyway). I can't say the PSU is dead for sure, but I also don't plan on checking. While the label says 30A for the 5V rail, apparently that is a conditional statement.